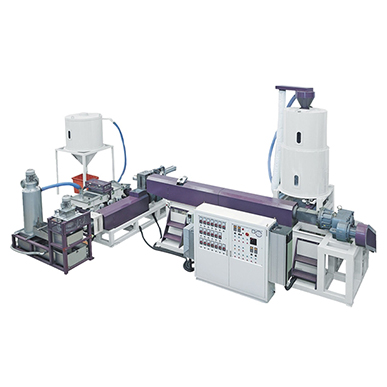

Plastic Waste Recycling Machines

Powering a Sustainable Future with Advanced Plastic Recycling Solutions

Recycling transforms used materials into new resources, cutting down on raw material use, reducing pollution, and saving energy. At Matila Industrial, Taiwan’s leading manufacturer of plastic recycling machines, we design high-efficiency, durable systems to make this process seamless. From shredding and washing to pelletizing, our solutions handle PET bottles, PP/PE films, and more, serving industries like agriculture, building, and packaging. Built for performance and sustainability, our machines deliver lasting value with minimal maintenance.

Not sure where to start? Just pick a machine, ask us any questions, and we’ll help you get set up.

♻ Why Choose Matila Equipment for Plastic Recycling?

- ☑ Complete Recycling Solutions:

From standalone machines to turnkey recycling lines, we deliver robust solutions for HDPE, LDPE, PP, PET, and other soft and rigid plastics. - ☑ Cutting-Edge Technology:

Our equipment features European gearboxes, high-efficiency ABB/HITACHI inverters, and PID+SCR temperature controllers for precise, reliable, and energy-saving operation. - ☑ Custom Engineering:

Every recycling line can be configured to meet your plant’s capacity, input material, and automation requirements. - ☑ Quality & Safety:

All machines are built to international standards, with a focus on durability, operator safety, and ease of maintenance.

Technical Highlights

- 💡 Output capacities from 100 kg/hr to 1,500 kg/hr, tailored to your needs.

- 💡 Advanced degassing, filtration, and modular pelletizing systems.

- 💡 Energy-saving design with optimized power consumption.

- 💡 Automation options for feeding, temperature control, and pellet cutting.

- 💡 Compatible with a wide range of plastics: HDPE, LDPE, LLDPE, PP, BOPP, PET, EVA, EPS, and more.

Industries We Serve

Customized solutions for sector-specific challenges:

- 🢖 Agriculture: Recycling mulch films

- 🢖 Packaging: Turnkey PET bottle-to-flake systems

- 🢖 Electronics: PP battery shall/ case

Industry Insights & Trends

The global demand for sustainable plastic recycling is accelerating. Modern recycling plants are integrating AI and smart automation for predictive maintenance, quality inspection, and process optimization. Matila’s systems are designed to support these advancements, enabling clients to stay ahead of regulatory requirements and market expectations.

Advantages Over Traditional Recycling Equipment

- 🢖 Integration: Matila provides multi-function recycling systems, whereas traditional setups often require multiple standalone machines.

- 🢖 Energy Efficiency: Our lines are optimized for lower power consumption, reducing operational costs compared to conventional equipment.

- 🢖 Automation: Advanced control systems enable automated monitoring and adjustments, minimizing manual intervention.

- 🢖 Output Quality: Consistent production of high-purity pellets reduces contamination risks common in traditional processes.

- 🢖 Maintenance: Modular design allows easier access and faster maintenance, improving uptime versus more complex traditional machinery.

Get Expert Support

Recycling reuses materials to save resources, cut pollution, and reduce energy use. At Matila Industrial, Taiwan’s top plastic recycling machine manufacturer, we craft efficient, durable systems for PET bottles, PP/PE films, and more. Our solutions ensure sustainability and lasting value with minimal maintenance.

Contact our team for a free consultation or tailored proposal to meet your needs.

Explore our plastic recycling machines below to find your ideal solution.

📞 +886-2-2619-2222 | ✉️ matila@matila.com.tw