E-news / Extrusion Control

The extrusion control is one of common system on the blown film machine. The function of extrusion control is using the program calculation to maintain a stable material feeding by weight and material output by extruder speed, in order to reach the same weight per same meter roll in the production.

Unlike the full set auto control system*, the extrusion control system doesn't control film width and film thickness, so the operator needs to adjust both the production sizes at the beginning before production starting.

💡Full set auto control system includes:

Dosing system + IBC + Smart air ring + Profile width & thickness control scanner

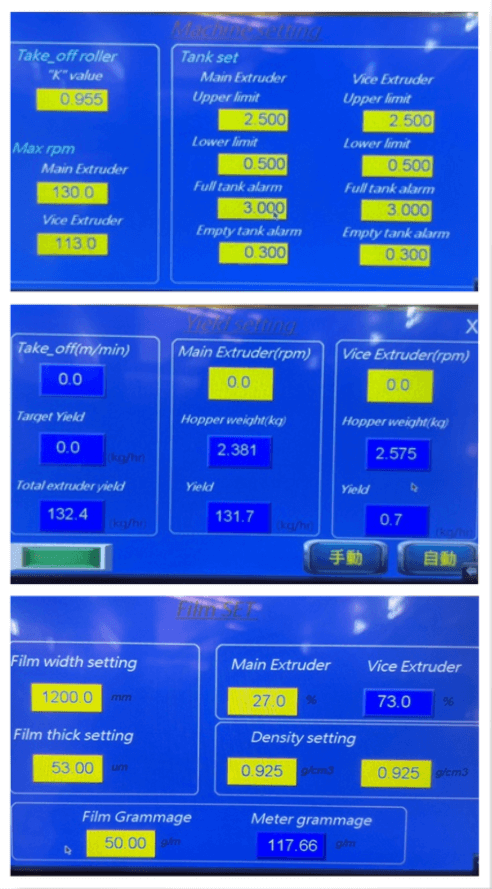

The extrusion control system only controls main extruder speed & line speed of the machine. The way it works is by setting the formula in the program; that is why operator needs to key-in the material information, such as film width, thickness, MFI and even density, therefore the system can calculate and control the production accordingly.

The extrusion control system only controls main extruder speed & line speed of the machine. The way it works is by setting the formula in the program; that is why operator needs to key-in the material information, such as film width, thickness, MFI and even density, therefore the system can calculate and control the production accordingly.

Moreover, just because the extrusion control system can only receive the actual weight from the scale under the material hopper, and from this actual weight + film width & thickness & MFI that the operator key-in, the system will control line speed and main extruders speed by the demand from a formula calculation.

Therefore, the production can maintain the stable material feeding by scale, main extruders speed and line speed to ensure the weight of each meter will be the same.