E-news / ALSC

Laser Screen Auto Clean Melt Filter

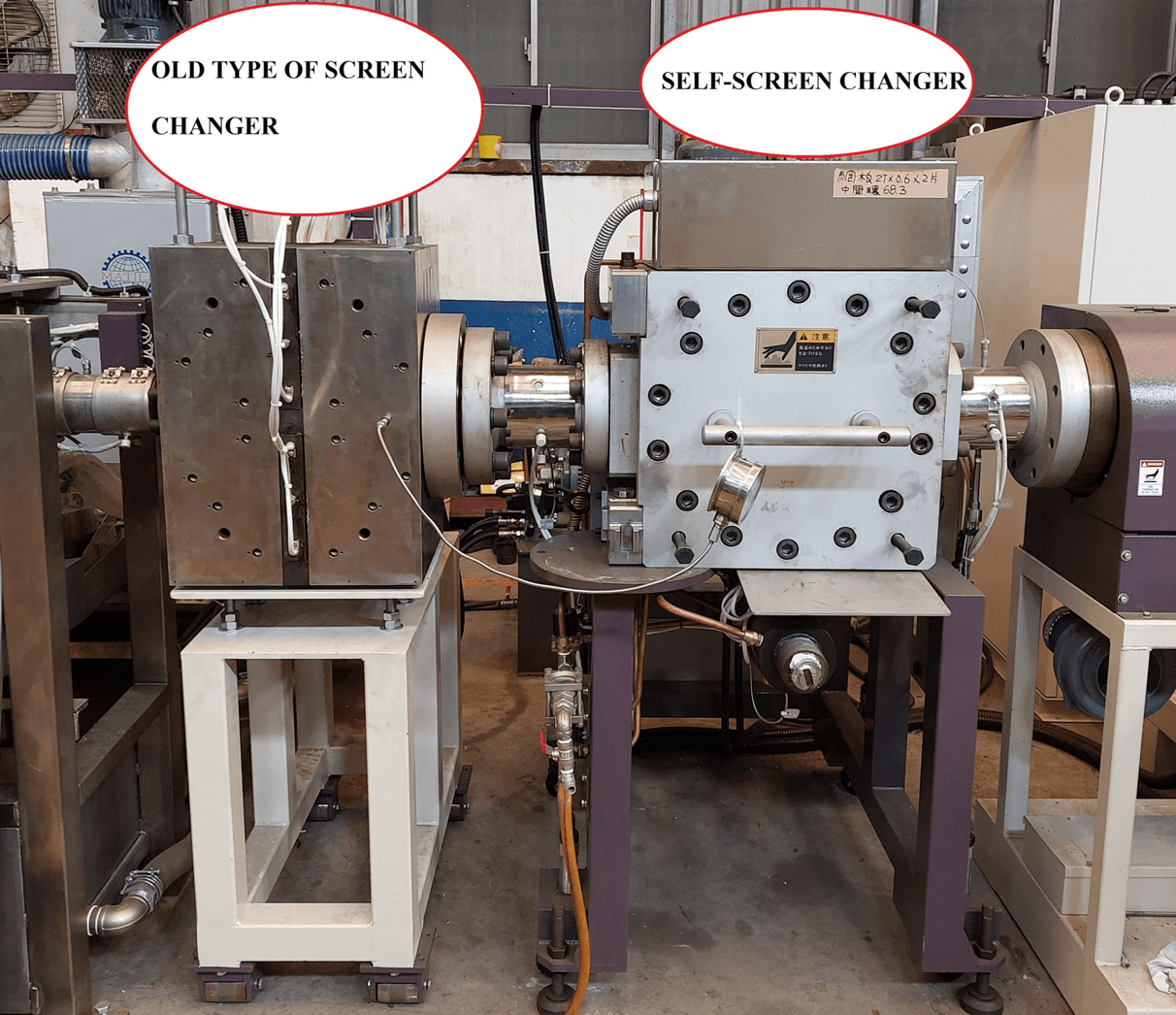

The new technology of screen changer

This system will have no mesh to clean or change, only plates with thousands of micro holes. When these micro holes are blocked, you can just put the plate in oven, so the blocked holes will be re-opened again, and you can reuse the plates for many times before changing it.

This system can remove the dirt to convert to pellets and will help to run machine in maximum speed without wasting time on changing the mesh as an old filter.

Comparison

| Old screen changer | Self-clean screen changer |

| Change or clean each 10 mins | Each month or 3 months, the plates will be put in oven |

| Labor needed | No need |

| Waste time | Save time |

| Mesh needed | No mesh |

| Capacity reduce to the frequency of stopping machine | Runs in full capacity |

| Waste money | Save money |

Purpose with 2 screen changers

Some of the customers they add another old screen changer, just to assure that the end product is high quality and without dirt. As with old screen changer, it needs to change the mesh for once or twice a day, depending on the contamination of the waste.